E-MOP™

E-MOP™ Electromagnetic Oil Spill Remediation Technology provides a system and a method for remediating oil spills on water and land. The technology uses electromagnetic pulses and specially timed magnetic fields to produce magnetic forces that move, lift and transport oil. This provides for an effective and nontoxic method for cleaning “produced” water, remediating toxic spills, and restoring land and waterways. The technology utilizes materials that are environmentally safe, reusable and natural.

Oil forms a unique bond with micron-sized magnetite particles. This bond is exploited as the combination of oil and magnetite are rendered magnetic in the presence of magnetic fields. Viscosity effects are enhanced, the ability to confine, attract and move the spills is increased, and the remediation process is controlled without the use of dispersants and other harmful chemicals and methods. Solenoidal coils and other magnets are used in the process to produce the magnetic field gradients that provide the forces necessary to move the magnetized mixture, collect it, and separate the particles for potential reuse and the oil for possible reclamation.

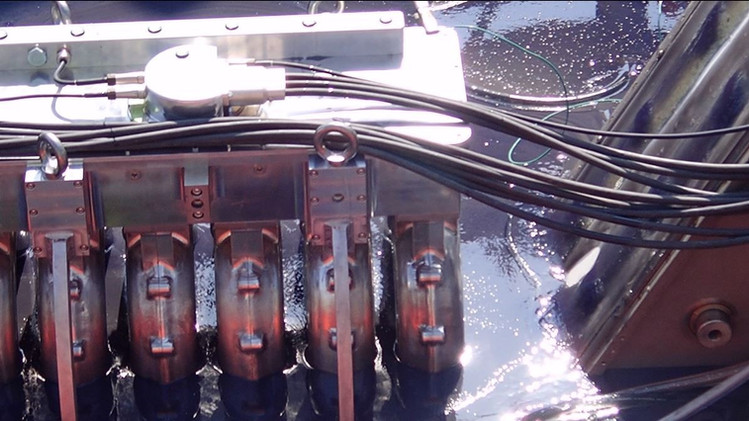

The solenoids in the system form an active electromagnetic boom (e-boom) which differs fundamentally from the passive booms that are common today. The e-booms collect and transport magnetized mixture within the reach of its fields (on and below the surface) and deliver it to its interface with a magnetic ramp (e-ramp). This includes mixtures that may be several inches below the surface as in the case with heavy-oil spills. The ramp in turn collects the mixture and separates the magnetite for reuse while actively rejecting water in the process.

VIDEO: Electromagnetic Boom - Ramp Concept

The system also targets oil at the micron-scale (the size of the particles used) which is normally either not visible to the naked eye or reveals itself in the form of a sheen. On beaches, rocks, marshlands, roads and other solid surfaces, magneto-rheological effects are exploited to lift and remove the oil that coagulates and creates environmental damage to plants and wildlife. In addition, electromagnetic remediation provides a method for filtering and cleaning water for reuse in conjunction with magnetizable organic hydrophobic absorbents.

E-MOP was successfully validated in a test environment at the Ohmsett National Oil Spill Response Research & Renewable Energy Test Facility in 2019, delivering a 97.2% recovery and separation of oil from water.

Applications of E-MOP

In addition to large- and small-scale oil spill applications, the technology can be used in industrial applications to filter and remove flocculant from water at treatment plants, process and reclaim “produced” water associated with fracking and oil refinery processes, and clean daily spills in harbors, ports, laboratories and businesses that work with large and small volumes of oil. Water associated with many of these applications is typically contaminated by oil. This water is not potable and does not meet standards for normal disposal.

E-MOP Advantages

Collects oil within the reach of the magnetic fields

Reduces the oil spread rate and aids confinement due to forces between the magnetic particles and the hydrocarbon bonds

Actively attracts the oil for collection via the active e-boom

Allows oil to be efficiently lifted off surfaces (magneto-rheological effects)

Collects oil at both surface and subsurface

Works just as well in cold water spills

Combats wave action by orienting itself in the wave direction

Separates oil from the water and magnetite so all can be reused

Environmentally benign—safe, nontoxic, reusable